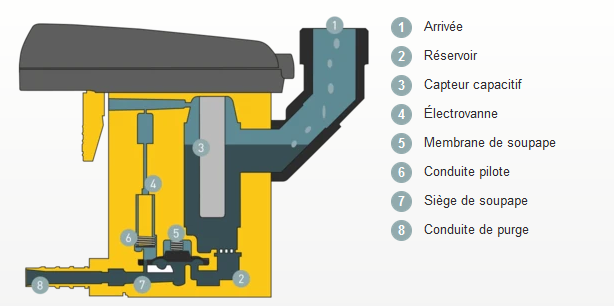

In Eco-Drains, a patented pilot air control design separates the working components from the condensate chamber, providing worry free operation and high reliability. Other drain types put valves in direct contact with contaminated condensate, which clogs control lines and disrupts solenoid movement. Reliable Components Eco-Drains’ rugged cast aluminum housing and superior diaphragm valve technology ensure many years of reliable service. 1 KAESER Equipment Card 1 KAESER Equipment Card 2 Number of the KAESER Equipment Card 1. The user name is required for a manual log on without Equipment Card. The number shown on the rear of the Equipment Card is also the user name. Dry contacts enable remote monitoring and alarm functions. This plastic sleeve is attached to the rear of the controller in the control cabinet. Eco-Drains feature LEDs that indicate power, valve and alarm status as well as a test button to manually check drain operation. This sensor’s high accuracy eliminates compressed air losses. Accurate Electronic Control A capacitance sensor monitors condensate levels in the drain and activates the Eco-Drain's solenoid. They sense when liquid is present and automatically discharge it, but they only open when condensate is present, saving costly compressed air. Unlike manual valves and timed solenoids, Eco- Drains ensure that condensate does not build up in your system. Kaeser Eco-Drains automatically remove condensate from aftercoolers, filters, dryers, tanks and air lines. If left in your air system, it will contaminate products and cause equipment malfunction. Mostly water, it also contains oils, dirt and other material. Remove Condensate Condensate is a natural by-product of compressed air.

0 kommentar(er)

0 kommentar(er)